Today, polyester fibers are usually produced in two methods, single-stage and two-stage.

A: One-step technology for the production of polyester fibers

This method is usually used to produce thicker fibers, which are less sensitive. In this method, the volume of equipment and finally the cost of energy consumption is less.

As mentioned before, in the production of thick products, it is possible to use recycled PET in the right proportion with polyester chips to reduce material costs, and the amount of recycled PET consumption depends on the type of product produced, and the thicker the product, the PET consumption ratio There is more recycling.

In the fiber production process, due to the sensitivity of polyester to moisture, first the Crystallization process and then Drying is performed. The humidity of raw chips is usually between 500-600 ppm and for consumption should be reduced to less than 35 ppm. Otherwise, during extrusion melting, the polyester will be hydrolyzed and eventually the filament will be cut, which will have a severe negative effect on the spinning efficiency.

After drying, the polyester chips are fed to the extruder by weight. To melt, to provide the necessary pressure for filtration and transfer in the transfer line. At the end of the branches of the polymer transmission line, the spin pack is pumped to the spin pack spinners by mitering the spin pumps (volume pumps). The function of the spinning packs is to uniformize the polymer, filter it, and finally, in the Spinneret section, convert the molten polymer into fibers.

The fibers coming out of the pack are molten, so by means of Quench Air the fibers are cooled during stretching and become solid. The force required to pull the fibers in the spinning section is provided by the Take up section. After cooling and solidifying, the fibers are impregnated with water and oil solution by finishing jets. This is done to reduce the friction between the fibers and the metal and ceramic surfaces, to reduce the effects of static electricity and the fibers to stick together, and then the fibers are sent as a band to the tensile region.

Due to the fact that the fibers produced in the spinning area are mainly affected by the tensile force in molten and pasty conditions, they lack the necessary orientation for the necessary physical properties, so they are directed to the tensile area and in this area under the influence of heat and The applied mechanical force is drawn by the tension rollers and the necessary orientation is created in the fibers.

The fibers are then heated through a crimping machine to turn the fibers from flat to crimped. This is done to allow the fibers to collide with each other in downstream processes. Then, in order to remove the residual forces in the fibers and stabilize the properties in the fibers, as well as to control the amount of fiber dye, the tape is passed through the Heat Setting Oven to stabilize all properties including consistency, extension, detox, dye and fold. It is eaten and packed in a batch.

B: Two-stage technology for the production of polyester fibers

In the production of fine fibers with very controlled physical properties and high quality, it is not possible to produce in a one-step process and also the use of recycled PET is not possible.

Therefore, these types of fibers are produced in a two-step method.

The two-step process in the spinning section is similar to the previous one, except that the fibers are stored in the spinning tins after spinning.

Then a number of joints are placed in the area of traction and stretched.

This method is done to control the spinning parameters so that in case of any problems, it can be corrected in the next step to achieve a reliable product and a degree. In the traction part, in the one-stage type, the traction is done in one stage, but in the two-stage production system, the traction is generally done in three stages and in stages, but in the two-stage production system, the traction is generally done in three stages and in stages. This is done so that the fine fibers do not tear and do not lead to the production of fibers with thickness or unwanted parameters. Tensioning is usually done in three stages with ratios of about 2.2.1 ٫ 3.1.2. Fine fibers are usually produced with cutting lengths of 32 and 38 mm. In this type of fiber production, it is usually possible to produce Micro fibers with a fineness of 1.0-0.8 detox.

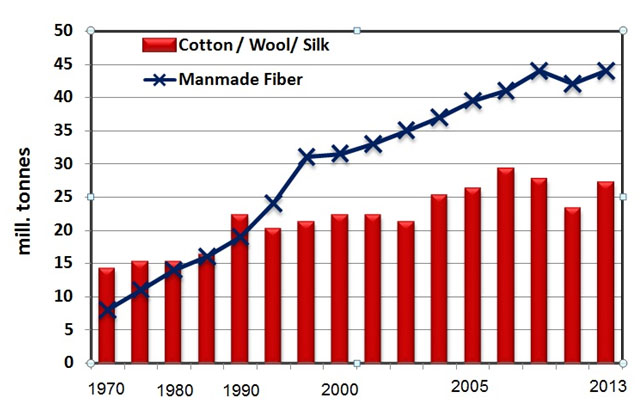

rs in the world are growing year by year compared to natural fibers. The diagram below clearly shows this.

rs in the world are growing year by year compared to natural fibers. The diagram below clearly shows this.